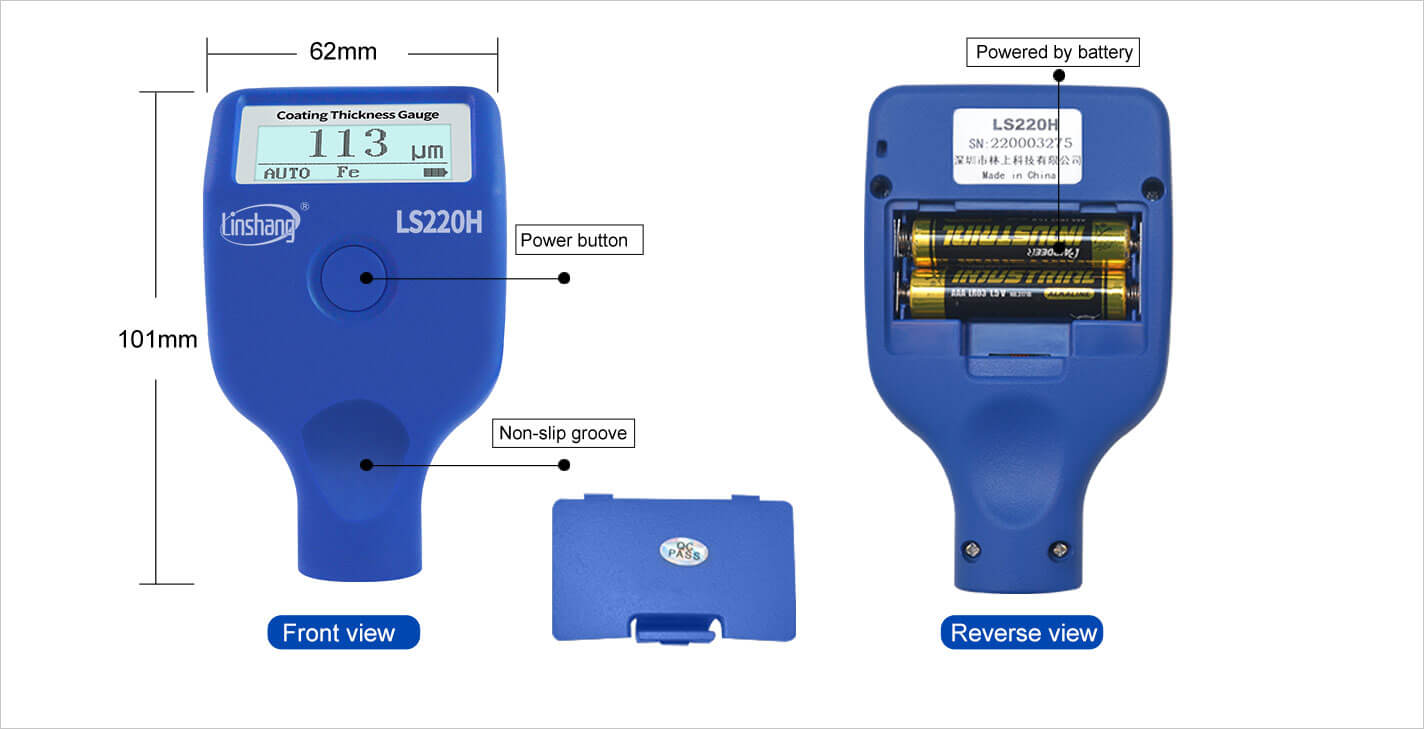

LS220H Dry Film Thickness Gauge

1. Measuring range: 0.0-5000μm

2. High-quality digital probe ensures accurate measurement and stable data

3. Dual use on ferrous/non-ferrous substrates, Identify substrate automatically

Description

LS220H coating thickness gauge four major advantages

LS220H is an integrated high-precision coating thickness gauge, which combines the Hall effect and Eddy current thickness measurement principles. Based on the Hall effect, the instrument can measure non-ferromagnetic coatings on ferromagnetic metal substrates, while under the Eddy current principle effect, it can measure non-conductive coatings on non-magnetic metal substrates.

- There are only four types of ferromagnetic metal elements at room temperature: iron, cobalt, nickel, and gadolinium.

- Common non-ferromagnetic metals: copper, aluminum, zinc, chromium, etc.

- Hall effect: can be used for the measurement of non-ferromagnetic coatings on ferromagnetic metal substrates.

- Eddy current: can be used for the measurement of non-conductive coatings on non-magnetic metal substrates.

|

Substrate |

Coating | Examples |

Yes/No |

| Ferromagnetic materials: iron, cobalt, nickel, gadolinium |

Non-ferromagnetic metal | 1. Galvanized iron copper plating |

√ |

| Non-metal materials | 1. Iron spray paint 2. Iron spray powder coating |

√ |

|

| Ferromagnetic material: Iron, cobalt, nickel and gadolinium | Iron nickel plating |

× |

|

| Non-ferromagnetic metal: Copper, aluminum, magnesium, zinc, etc. |

Non-conductive material | 1. Anodized ; aluminum surface 2. copper, spray paint |

√ |

Application

Parameters

| Parameter | Value |

|---|---|

| Probe tip | Ruby fixed |

| Measuring principle | Ferrous: Hall Effect / Non-ferrous: Eddy current |

| Probe type | Integrated probe |

| Measuring range | 0.0-5000μm |

| Resolution | 0.1μm: 0μm – 99.9μm 1μm: 100μm – 999μm 0.01mm: 1.00mm – 5.00mm |

| Accuracy | ≤±(3%H+2μm), H is the standard value |

| Unit | μm / mil |

| Measuring interval | 0.5s |

| Minimum measuring area | Ø = 25mm |

| Minimum curvature | Convex:5mm / Concave:25mm |

| Minimum substrate thickness | Fe:0.2mm / NFe:0.05mm |

| Display | 128×48 dot matrix LCD |

| Power supply | 2pcs of 1.5V AAA alkaline battery |

| Operation temperature range | 0℃-50℃ |

| Storage temperature range | -20℃-60℃ |

| Gauge size | 101*62*28 mm |

| Weight(with battery) | 79 g |

Feature

Dual-use probe for both iron and aluminum. The dry film thickness gauge has intelligent identification of measurement substrate and fast automatic transfer